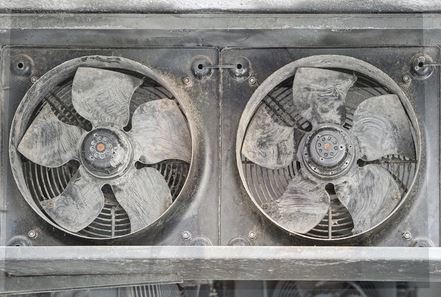

Do you have an industrial fan and something’s not right with it? What’s wrong?

Industrial fans can have problems due to debris, dust build-up, corrosion and other things. Sometimes they can be repaired, while other times it makes more sense to replace them.

What are some signs that your industrial fan isn’t working well and needs attention?

Too Much Noise

If your fan is making a lot of noise, and it’s an unusual amount of noise that you’re not used to, then the fan could be misaligned or damaged. For example, an impeller could be hitting the inlet or housing. It needs to be centered. When an impeller is crooked or damaged, you can expect excessive noise coming from a fan. If the impeller isn’t hitting the cut-off then the cut-off isn’t secure in the housing, it’s improperly positioned or it’s damaged. Maybe there’s a loose or bent shaft or perhaps a loose bearing. Or the belt drive is causing the excessive noise. This could be due to the sheave not being tight on the shaft. Belts can become worn and loose. They can also become oily and dirty. If you hear a squeaking sound, the fan might need lubrication. If you hear a rattle or whistle, check the dampers, elbows, ductwork, turning vanes and/or fins on coils. Rattles are often the result of vibrating ductwork or cabinet parts.

Not Enough Noise

If your fan is unusually quiet because it doesn’t seem to want to move at all, then you could have a mechanical or electrical problem. Blown fuses, broken belts, loose pulleys and/or the wrong voltage could be the culprit(s). Maybe it’s due to excessive line drop, inadequate wire size, a load inertia that’s excessive for the motor, or perhaps a seized bearing. If and when the fan is “too quiet” or not working, it needs some attention.

Not Enough Airflow

What about inadequate airflow? Maybe the impeller was installed backwards! Or it could be due to an incorrect blade angle setting, a missing cut-off, or misalignment with inlet collars. Fans might not perform properly if they get a dirty/clogged inlet. They can also experience inadequate running clearance, improper inlet cone-to-wheel fit, or incorrectly set inlet vane(s) or damper(s).

Not So Good Vibrations

Is your industrial fan vibrating too much? Maybe the impeller isn’t properly balanced. Or it could be the motor and sheaves aren’t balanced. Are the key lengths correct? What about the fan shaft seals– are they rubbing? These are all things to consider if your industrial fan has excessive vibration.

Dynamic Fan Is Here to Help

Dynamic Fan of New Jersey has been in business for over 30 years helping countless clients with their industrial (and commercial) fan needs. Located in Pine Brook, NJ, Dynamic Fan has the experience, equipment and workers needed to handle all types of industrial fan projects. If you think your fan(s) might need repairs or retrofitting, Dynamic Fan can help with an analysis and replacement parts. Our customer first philosophy means we give detailed attention to your needs, making sure things are done correctly and that your fan(s) will serve you well for years to come. Don’t hesitate to call Dynamic Fan at 973-244-2422 to ask questions and/or share concerns. On-site service is available.